Scientific Research Projects

The German model of ‘craftsmanship’

Uniting together and practicing the quality of perseverance, Quan workers have established a professional team of engineers, who have gradually formed their own core technology with their thick R&D strength and innovative spirit. Our current team of engineers includes several veteran engineers who are the most senior within the industry.

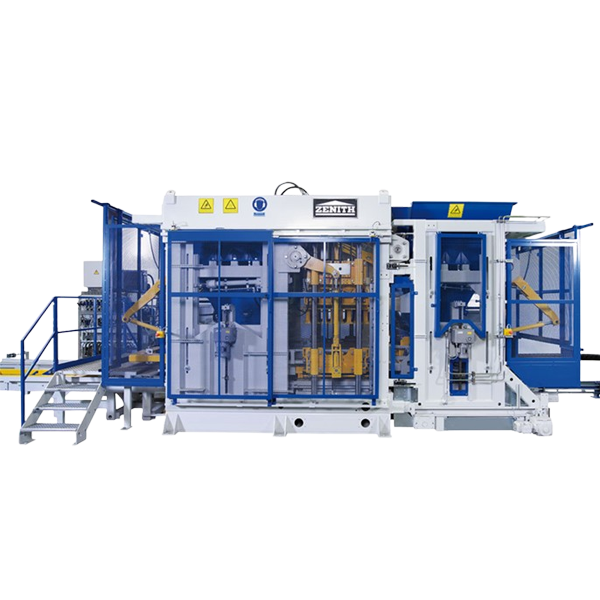

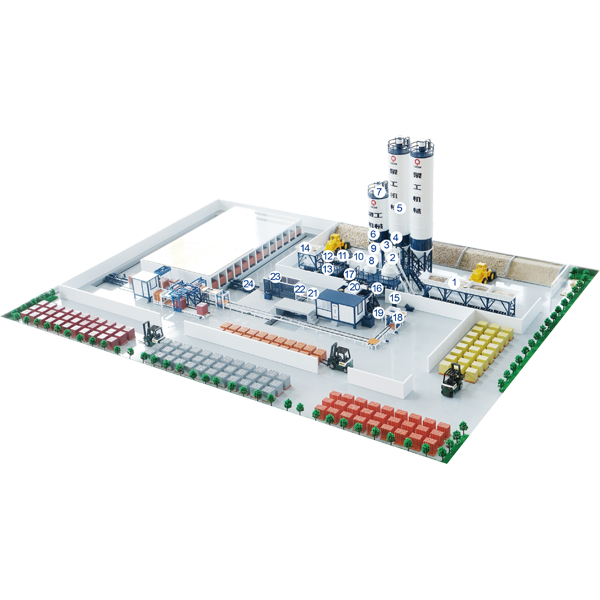

In addition, the company has acquired the technology and talents of Omak, a famous German block machine manufacturer with a history of nearly 100 years. In June 2013, the company also set up a German technology research and development centre, which is committed to creating environmentally friendly, high-end brick-making factories tailor-made for global users. The company has also become a strategic partner with American Mastermatic Company. Based on the introduction of advanced technology from Europe and the United States, we integrate the company's own advantages of industry technology and experience, and apply them to the design of products. At present, many of our equipments have the advanced genes of European and American machinery industry.

With such a strong technical international column, the company is on the road of technical reform and research and development smoothly. Based on the introduction of advanced technology from Europe and America, we have developed more than thirty kinds of high-performance and high-quality products with independent intellectual property rights, and our products are steadily ranked at the forefront of the domestic brands, and we have won steadily step by step in the field of machinery industry, and we have become the only high-end operator in China with the integrated solution of brick-making. Creating value for customers is the sacred responsibility of CHUANGONG! Our products will also continue to implement the requirements of ISO quality management system.

Quality Management System

【General Requirements】

1, the company according to ISO9001: 2000 quality management system requirements for the establishment of quality management system, production, sales and other processes identified, the order of these processes and interactions have been identified, and each process in accordance with the requirements of the 5S standard suitable for the quality management of the enterprise.

2, in order to ensure the effective operation and control of the enterprise quality management system and the application process, the company has prepared the corresponding procedure documents, and supported by the relevant work instructions, specifications and so on.

3、In order to support the effective operation of these processes and the monitoring of these processes, the enterprise is equipped with the necessary manpower, facilities, financial and related information and other resources.

In order to monitor, measure and analyse the process of the operation of the quality management system of the plant, the enterprise implements the necessary measures to achieve the structure and continuous improvement planned for these processes.

[Documentation Requirements]

Our company establishes and maintains the documents of the quality management system according to the product formation process and characteristics covered by the system.

Documents include:

1, the general manager approved the release of the quality policy and quality objectives in accordance with the standard requirements of the preparation of the ‘Quality Manual’.

2, according to ‘ISO9001: 2000 quality management system requirements’ provisions of the preparation of the ‘document control procedures,’ ‘record control procedures,’ ‘internal audit procedures,’ ‘nonconforming goods control procedures,’ ‘corrective measures to implement the procedure,’ ‘preventive measures to implement the procedure,’ and so on.

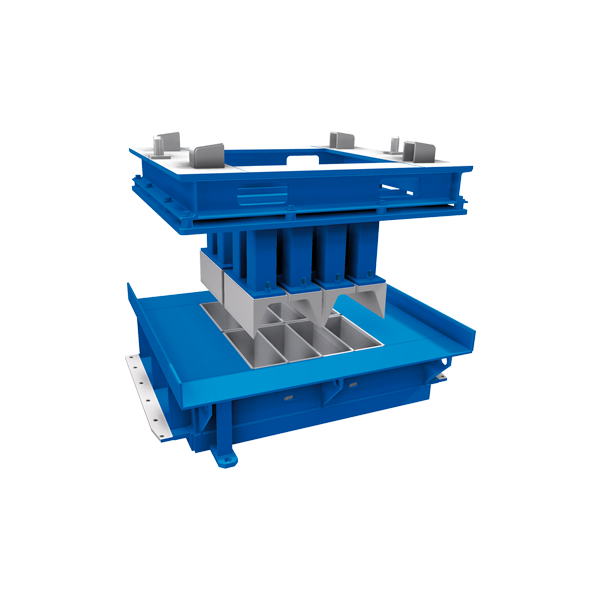

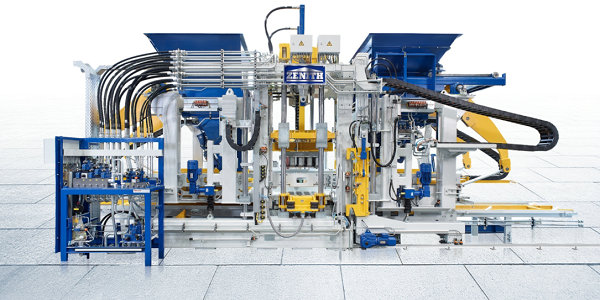

Pallet-free technology

The German model of ‘craftsmanship

Intelligent interactive system

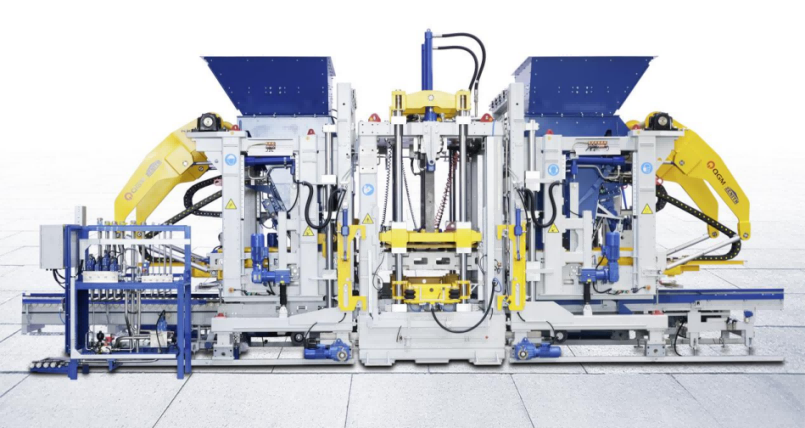

Hydraulic drive

Synchronous coaxial motion

Polystyrene foam insertion device

Intelligent operation

The equipment adopts international advanced intelligent interactive system, equipped with Siemens touch screen and data input/output device, the system has the functions of product formula management and operation data collection, and has multi-language available. The visualised operation interface is friendly, and the control system includes safety logic control and fault diagnosis system.

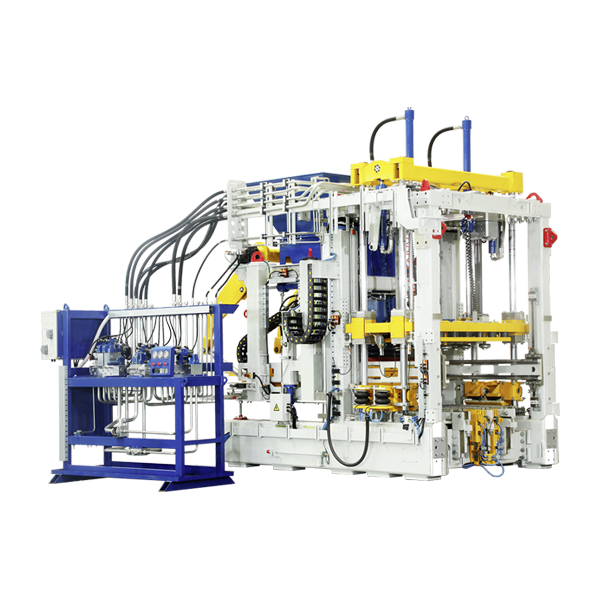

Hydraulic drive system

The hydraulic power consists of two sets of UNITED STAR piston pumps. The speed and pressure of the hydraulic action can be precisely controlled simultaneously or independently by means of iso-proportional valves, and all parameters can be set on the touch screen. The main movements of the machine, such as the movement of the vibration table, the lifting of the mould frame and the press head, and the movement of the fabric frame, are driven by Zenit's self-developed hydraulic system.

Mobile production

The machine is equipped with high rigid guideway travelling wheels for mobile production. The hydraulic motor drive is smooth and reliable, and the front wheels have a hydraulic brake system for precise positioning. Production movement, which can be set via touch screen control.

Coaxial synchronised movement

The synchronised movement of the machine's mould frames and press heads along the large-size guide columns and guide shafts by means of chains and lever shafts ensures safe, stable and precise movement of the mould frames and press heads; optional linear encoders are also available to further enhance the precision of the movement.

Multi-functional Fabrication System

The system consists of a hopper, guide rails, fabric box and lifting device; a unique hydraulically driven mould scraper ensures product surface cleanliness; the fabric box is equipped with a hydraulically driven quick fabric grill for uniformity; a height adjustable mould brush fixed to the fabric box is used to clean the upper part of the mould.