Sponge City Construction

The German model of ‘craftsmanship’

‘Priority should be given to leaving limited rainwater behind when upgrading urban drainage systems, prioritising the greater use of natural forces to drain water, and building sponge cities that naturally store, naturally infiltrate and naturally purify.’

——Speech by General Secretary Xi Jinping at the Central Working Conference on Urbanisation

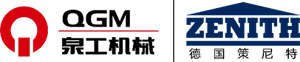

Zenit has long been committed to the technical research and development of environmental performance of products, including permeable ground system research, by Zenit 940 equipment production of permeable brick products with excellent performance, are over and partially exceeded the CJJ/T188-2012 ‘Permeable Brick Pavement Technical Specification’, JC/T945-2005 ‘permeable brick’ and other national standards, the product is widely used in various municipal, square and The products are widely used in various municipal, plaza and landscape projects.

Percolated Brick

Application Cases of Permeable Brick

Comprehensive Utilisation of Construction Waste

The German model of ‘craftsmanship’

‘The annual generation of industrial solid waste in China is about 3.23 billion tonnes, and the annual removal of municipal domestic waste is about 171 million tonnes, but due to the relative inadequacy of China's waste disposal capacity, a large amount of solid waste has not been processed and disposed of in a timely and effective manner.’

——《Opinions on Promoting Collaborative Resource-based Treatment of Municipal and Industrial Waste in Production Processes》

In the use of construction waste resources, Germany Zenit walks in the forefront of the world.

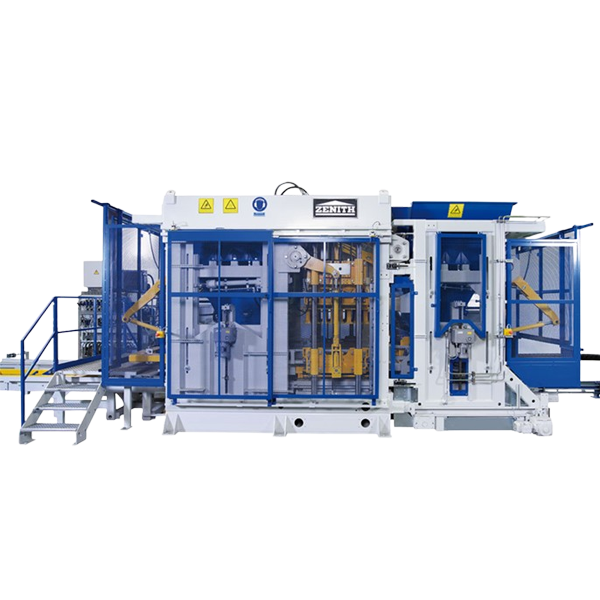

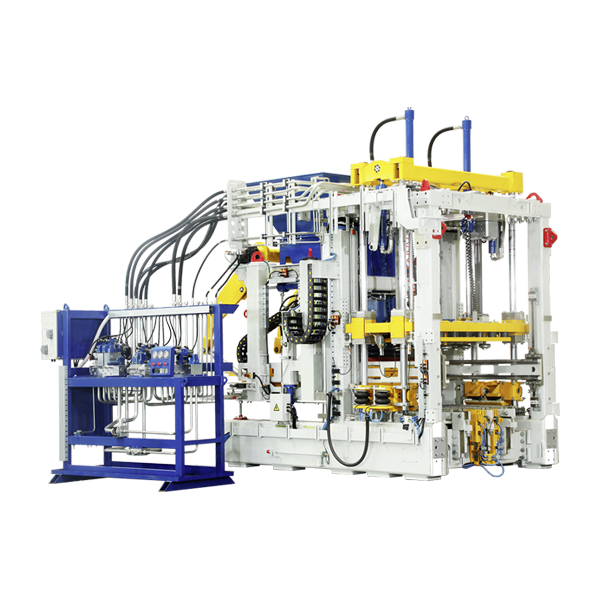

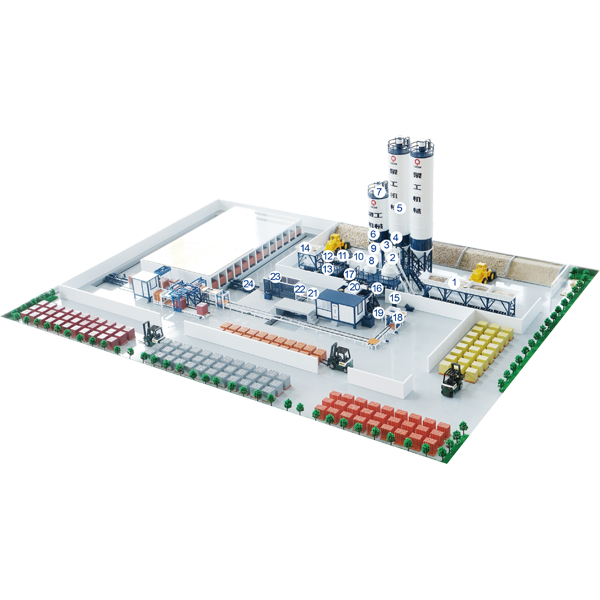

To realise the resourceful use of construction waste to make bricks, it is necessary to go through five processes: sorting, crushing, screening, brick making and maintenance. The performance of the finished bricks made of construction waste depends mainly on the performance of the raw materials and the moulding machine technology! German Zenit's pallet-free brick-making equipment takes the crushed and screened construction waste as the main raw material, and the construction waste can account for more than 80% of the total raw material. The unique pallet-free technology allows the vibration force to reach the product directly, resulting in better compaction, better compression and frost resistance, and no secondary pollution during the production process!

The products produced by Zenit equipment with construction waste as the main raw material include sponge city construction permeable bricks, pavement bricks, wall block bricks and many other products, which have been gradually included in the catalogue of green building materials, government procurement catalogue, and are widely used in municipal projects such as city roads, rivers, parks, squares and other municipal projects. With the optimisation of the development environment of the industry, the development of construction waste resource utilisation will have a very considerable prospect.

Flow chart of reusing construction waste to make bricks

Products made from construction waste