Company Profile

A model of German "craftsmanship"

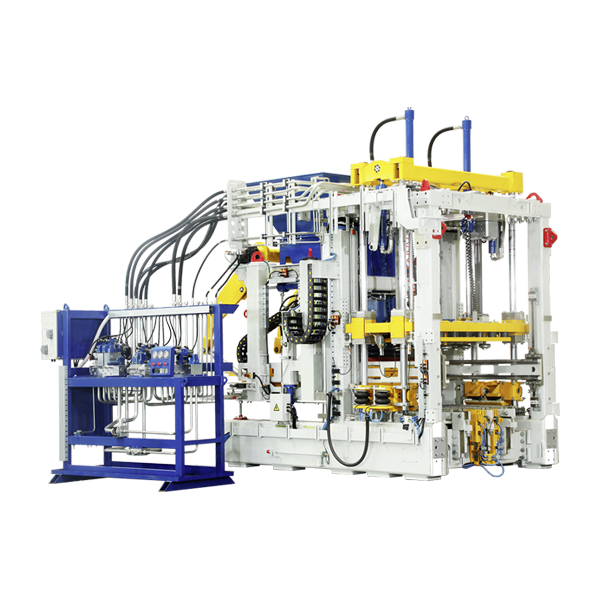

In 1953, Zenith Maschinenfabrik GmbH (Zenith Maschinenfabrik GmbH) was founded in Germany. It has now developed into one of the most famous and influential manufacturers of concrete block forming machines and complete equipment in the world. one. The company has long been committed to the R&D and production of pallet-free brick making machines. It has the world's leading pallet-free equipment manufacturing technology, and its market share of high-end brick making machines is firmly at the forefront. Zenit products are famous for their quality and safety, with extremely low failure rates, labor saving and high efficiency. They enjoy an international reputation. So far, Zenit has more than 7,500 customers around the world, and its product line covers mobile multi-level products. , fixed multi-layer, fixed single pallet and fully automatic equipment single pallet and other series of production lines.

In 2014, the German company Zenit was wholly acquired by Quangong Machinery Co., Ltd., a leading enterprise in China's brick-making machine industry, and became a member company of QGM. The German Zenit company used QGM's complete sales and service system. Provide our customers with advanced German technology, brick-making experience and quality services.

Development History

Founded in Germany in 1953, Zenit Machinery Manufacturing Co., Ltd. has developed into one of the world's most well-known and influential manufacturers of concrete block forming machines and complete equipment. The company has long been committed to the R&D and production of pallet-free brick making machines. It has the world's leading pallet-free equipment manufacturing technology, and its market share of high-end brick making machines is firmly at the forefront. Zenith products are famous for their quality and safety, with extremely low failure rate, labor saving and high efficiency. They enjoy an international reputation. So far, Zenit has more than 7,500 customers around the world, and its product line covers mobile multi-level products. , fixed multi-layer, fixed single pallet and fully automatic equipment single pallet and other series of production lines.

-

-

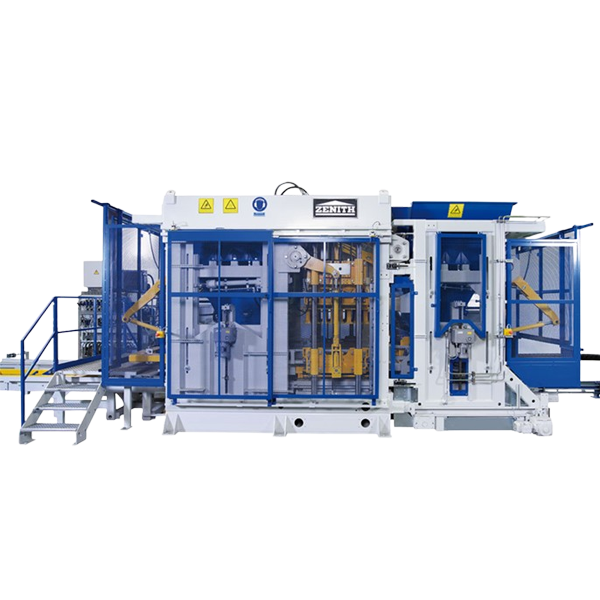

Zenit upgraded the Big Mac 875 with the latest electronic control technology and became the Zenit 1800 fully automatic production line;

-

Zenit merged into QGM and became a member company.

-

-

Zenith has developed the world-leading Zenith 1500 fully automatic production line.

-

-

Zenith has shipped 10,000 sets of equipment worldwide.

-

-

Zenith has developed the highly efficient Zenith 1200 fully automatic production line.

-

-

Zenith 844 has shipped 1,000 units cumulatively.

-

-

The total number of Zenith all-round concrete product forming machines 940 shipped reached 1,000.

-

-

Zenith has developed the world's largest brick-making machine production line, the Mega 875

-

-

Developed a mother-and-child vehicle with unique technology.

-

-

Developed a unique closed production system.

-

-

Developed a new generation of brick making machine "HB 865", which is low-maintenance and has automatic adjustment of the material distribution in the material cart and automatic mold replacement when producing paving bricks with coverings.

-

-

Zenith branch office established in Istanbul, Turkey, responsible for sales and service in Türkiye and surrounding former Soviet countries.

-

-

Zenith 913 has shipped more than 4,000 units in total.

-

-

The first fixed pallet brick-making machine "860" was developed, taking the first step into the fixed pallet brick-making machine market.

-

-

Cumulative sales of Zenith 913 exceeded 2,500 units.

-

-

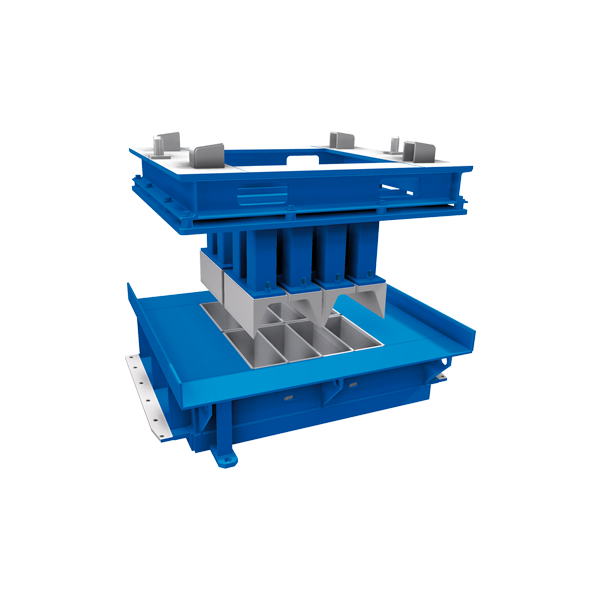

In order to better serve customers, Zenith expanded its production scale and began to professionally design and manufacture brick machine molds.

-

-

Developed the first fixed-type single-board computer "HB 810".

-

-

The world's first fixed-type pallet-free stacking brick-making machine 828 was developed, which was later improved to the fixed-type pallet-free stacking brick-making machine 844.

-

-

Developed the world's first mobile pallet-free brick-making machine "HB 938", which was later improved to 940 mobile pallet-free stacking brick-making machine.

-

-

Zenith 913 has shipped 1,000 units in total.

-

-

The Zenith 913 brick making machine produced the largest concrete prefabricated product at the time for a Belgian canal project.

-

-

Development of the first brick-making machine with a cover, the "HB 927" "Janus".

-

-

Zenith Company of Germany was established; it produced the first artificially fed brick-making machine "604", which was later improved to become the Zenith 913 mobile brick-making machine.

Leader's Speech

A model of German "craftsmanship"

Corporate Environment

A model of German "craftsmanship"

Zenith

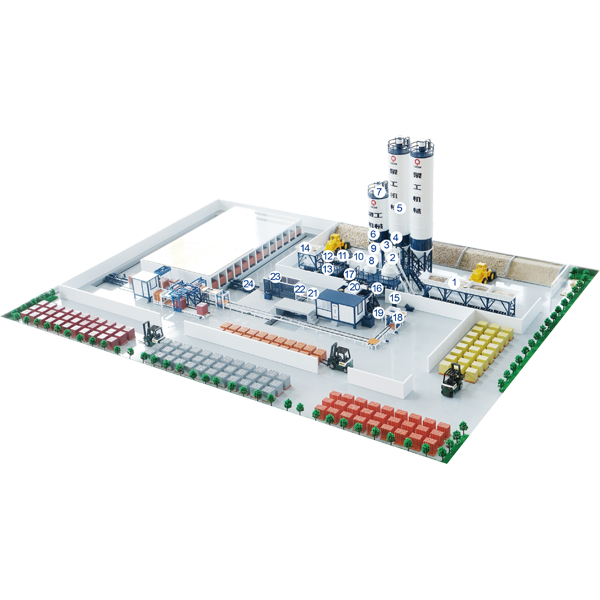

Company bird's eye view

Zenith Corporation (partial)

The company's core management team

A corner of the technology center

A corner of the conference room office area

Quangong Group

A model of German "craftsmanship"

Fujian Quangong Co., Ltd. was founded in 1979 and is headquartered in Quanzhou, Fujian. It is a high-tech enterprise specializing in the research and development, manufacturing and sales of brick-making machinery and equipment. Its business covers concrete block equipment, aerated concrete equipment and prefabricated building equipment. It has now developed into China's largest multinational brick-making integrated solution operator, with member companies such as Germany's Zenith Company and Austria's Zenith Mould Company. The company has a total asset of 1 billion, an annual output value of over 600 million, and more than 500 engineers and technicians of various types.

As a leading enterprise in the domestic brick machine industry, Quangong Co., Ltd. has always adhered to the business philosophy of "quality determines value, and professionalism builds career". On the basis of integrating German advanced technology, it actively innovates and develops to form its own core technology. Up to now, the company has won more than 140 product patents, including 5 invention patents authorized by the State Intellectual Property Office. Under the trend of "Industry 4.0", Quangong Co., Ltd. actively explores the use of "Internet +" thinking to improve enterprises and carry out the "integration of industrialization and informatization". The company's latest independently developed intelligent equipment cloud service platform system, relying on advanced Internet technology, can provide timely remote maintenance for customers in any corner of the world.

Over the years, QGM has won the national honorary titles of China Manufacturing Single Champion Demonstration Enterprise of the Ministry of Industry and Information Technology, Service-oriented Manufacturing Demonstration Project Enterprise of the Ministry of Industry and Information Technology, High-tech Enterprise, National New Wall Material Equipment Leading Enterprise, China Building Materials Industry Standard Drafting Unit, China Industrial Demonstration Unit, etc., and serves as:

Vice Chairman Unit of China Building Block Association;

Vice Chairman Unit of Wall Material Innovation Working Committee of China Circular Economy Association;

Vice Chairman Unit of China Sand and Stone Association, Vice Chairman Unit of Aggregate Branch of China Sand and Stone Association;

Vice Chairman Unit of Concrete Products Machinery Branch of China Construction Machinery Industry Association;

Vice Chairman Unit of Quanzhou Equipment Manufacturing Industry Association.

Adhering to the concept of "becoming an integrated brick-making solution operator with service and quality", QGM fully implements IS09001 quality management system and ISO14001 environmental management system. Its products are of first-class quality and have won honors such as China Well-known Trademark, Fujian Famous Trademark, Fujian Famous Brand Product, Patent Gold Award, etc., which are widely favored by the market. Its sales channels are spread across China and more than 120 countries and regions overseas, and its product sales are firmly in the forefront of domestic brands. In order to provide customers with the best service, QGM has established a high-quality service team, with 25 offices in China and 10 offices overseas.

In 2014, QGM acquired Zenith, a world-renowned German manufacturer of pallet-free brick machines with a history of more than 60 years, and established a technical research and development center in Germany, dedicated to absorbing the essence of Zenith's brick machine production line and integrating the latest technological elements of today's industry development.

In April 2016, QGM further accelerated its integration and acquired the mold manufacturing company of the Austrian Lehr Group (now renamed Zenith Mold Company), so that QGM's mold design technology has reached the international advanced level.

In July 2017, QGM and Germany's Soma joined forces to reach a strategic partnership, using the world's leading automated and intelligent prefabricated building prefabrication technology to promote the development of China's construction industrialization and provide Chinese customers with prefabricated building prefabrication technology and prefabricated parts fully automatic production lines suitable for the Chinese market. In the future, QGM will continue to be committed to the global research and development of brick making equipment technology to meet the ever-changing challenges in the field of construction machinery.

Founded in Germany in 1953, Zenit Machinery Manufacturing Co., Ltd. has developed into one of the world's most well-known and influential manufacturers of concrete block forming machines and complete equipment. The company has long been committed to the R&D and production of pallet-free brick making machines. It has the world's leading pallet-free equipment manufacturing technology, and its market share of high-end brick making machines is firmly at the forefront. Zenith products are famous for their quality and safety, with extremely low failure rate, labor saving and high efficiency. They enjoy an international reputation. So far, Zenit has more than 7,500 customers around the world, and its product line covers mobile multi-level products. , fixed multi-layer, fixed single pallet and fully automatic equipment single pallet and other series of production lines.

Founded in Germany in 1953, Zenit Machinery Manufacturing Co., Ltd. has developed into one of the world's most well-known and influential manufacturers of concrete block forming machines and complete equipment. The company has long been committed to the R&D and production of pallet-free brick making machines. It has the world's leading pallet-free equipment manufacturing technology, and its market share of high-end brick making machines is firmly at the forefront. Zenith products are famous for their quality and safety, with extremely low failure rate, labor saving and high efficiency. They enjoy an international reputation. So far, Zenit has more than 7,500 customers around the world, and its product line covers mobile multi-level products. , fixed multi-layer, fixed single pallet and fully automatic equipment single pallet and other series of production lines.